with Fiber

Reactive Dyes

Why

should the wool people have all the dyeing

fun? Fiber reactive dyes are specifically

designed for dyeing plant fibers: cotton,

linen, rayon, hemp, ramie, bamboo - even

rattan and nettle. The dyes are safe, light

and color-fast, come in a huge rainbow of

colors, and can dye anything that originally

came from a plant. Why

should the wool people have all the dyeing

fun? Fiber reactive dyes are specifically

designed for dyeing plant fibers: cotton,

linen, rayon, hemp, ramie, bamboo - even

rattan and nettle. The dyes are safe, light

and color-fast, come in a huge rainbow of

colors, and can dye anything that originally

came from a plant.

Fiber reactive dyes are also

referred to as cold-water dyes, because they

do not require high temperatures to make the

dyes permanent: no microwaves or boiling water

required.

Unlike acid dyes, these dyes react in an alkaline

environment, and so require the addition of

a base instead of an acid to activate the dyes.

My base-of-choice is soda ash (lye). It's best

to buy soda ash in its pure form from a dye

supplier. However you find it, make sure it

is pure and has no additives or anti-caking

agents.

Different fibers take dyes in differing amounts.

Linen will dye a slightly different color than

cotton, even if they are originally the same

color. Rayon takes dye vigorously and will

dye up in saturated colors. If you're trying

to dye a fiber a particular color, experiment

first.

The final color also depends on the original

color of the yarn. Remember yellow plus blue

makes green? If your original yarn is red and

you dye it with blue, the yarn will become

purple. Cream-colored yarn will always dye

a little duller than white yarn. If you are

looking for very bright colors, start with

a bleached white yarn.

Orange

yarn over-dyed with Fire Red, Peacock Blue,

and Plum.

You can also dye blends of

fibers, including acrylic, polyester, or protein

fiber blends. Fiber reactive dyes will NOT

dye synthetic fibers or most protein fibers.

The exception is silk, although

I prefer not to dye silk this way -- lye

is harsh on silk fibers and silk tends to lose

its soft hand when dyed this way. Silk shouldn't

be exposed to a soda ash solution more than

12 hours or it will begin to destroy the fiber,

so you must rinse no later than 12 hours after

dyeing. Also, fiber reactive dyes do not produce

quite the same colors on silk as they do on

cotton -- especially black, which produces

a purple, deep blue, or dark green instead.

Dye

results depend on the yarn construction and

content, but as a rule most man-made/plant

fiber blends will look heathered after dyeing

and appear much more pale than 100% plant fiber.

One special note about cotton:

cotton is sometimes treated in a process called

mercerization, which makes the fibers sleeker,

shinier, and more receptive to dye. A mercerized

cotton will dye into more brilliant colors

than non-mercerized cotton. Mercerization is

not always marked on the yarn label, but it's

usually easy to tell: mercerized cotton will

have a sheen, somewhat like silk. Non-mercerized

cotton's surface looks and feels more matte.

Undyed yarns

dyed

with Lemon Yellow

dyed with

Fire Red

dyed with

Peacock Blue

dyed with Plum

Fiber reactive dyes are considered

fairly safe to use when they are liquid form.

They are more dangerous as powder, and you

should use caution and the appropriate tools

when handling them. The dye particles are very

fine to enable them to dissolve more easily

in water, but that same property makes them

unsafe to breathe and prone to floating in

the air even with a small disturbance.

Use a dust mask when handling

the dye powder and powdered soda ash, one certified

by a government agency as safe for small particulates

(for example, in the U.S., use a dust mask

approved by NIOSH). I also recommend that when

working with the powders, you do it out of

doors: breezes can blow away fine particles

so that you do not breathe them.

Because lye is caustic and dyes will dye ANY

plant fiber and temporarily stain most protein

fibers, including your skin, wear goggles and

gloves while working. Lightweight disposable

latex or vinyl gloves are fine, although I

prefer heavier latex gloves because they can

be used again and again. Yes, goggles are annoying,

but spending 30 minutes rinsing your eyes out

because you splashed dye or lye in them is

not fun. Wear goggles.

A couple more safety things: don't use any

of your dye tools for eating or cooking, and

keep dyes away from small children and animals

- you don't know what they might do.

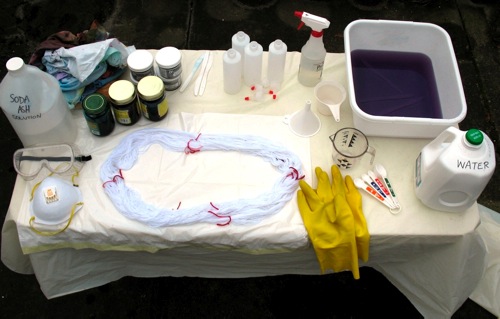

- Fiber reactive dyes

- soda ash

- Synthrapol

- water softener, if you have hard

water. Minerals in water can disrupt the

dye process. Dye suppliers often carry this.

- dusk

mask, certified for small particulates

- goggles

- rubber or vinyl gloves

- old clothes to wear

while dyeing, which you don't mind getting

stained

- a plastic drop-cloth to cover your work

surface

- several rags for wiping up spills

- cups or jars for mixing dyes

- measuring spoons

- measuring cup

- rinse basin - such as plastic dishwashing

container

- yarn soak basin - another plastic container

for pre-soaking the yarn

- stirring tools - I use plastic knives (spoons

don't work as well)

- gallon jug for mixing soda ash solution

- jug for water

- plastic bags for finished yarn. These should

be large enough to accommodate a skein of

yarn without the yarn edges touching.

- funnel

- yarn for tying the dye skeins.

- spray bottle full of plain water for cleanup

- Optional: dye applicators:

squeeze bottles (such as those used for hair

dyes), spray bottles, sponge-top applicators

I keep a rinse basin and

a jug of water on my work surface, and any

item I dirty (measuring cups, spoons, stirrers,

funnels, etc) I throw into the rinse basin

with some water. It simplifies cleanup and

reduces the amount of dye powder that might

be floating around in the air.

1. Prepare your yarn. Make the ball into a

hank, and then tie LOOSELY in at least 4 places

around the hank. When tying, make a figure-8

tie by bringing the tying yarn from the bottom

through the skein, over the top, through the

skein going the other directions, and tied

at the bottom.

2. Don your dusk mask and goggles, prepare

your workspace, and fill your water jug with

warm (~105 F) water (and water softener, if

needed)

3. Mix soda ash fixer solution. I use the

ratio suggested by Dharma Trading Company:

1 cup soda ash in 1 gallon hot water. Soda

ash dissolves better in hot water, and it will

have cooled to warm by the time you're ready

to dye. I use a funnel to measure the soda

ash directly into a gallon jug, fill with hot

water, cap the jug, then shake shake shake.

Add water softener if needed.

4. Once the soda ash is completely dissolved,

pour some of it into a plastic basin. Put your

prepared yarn into the basin, completely submerging

it. Let it soak for 20 minutes or more. You

can reuse this fixer solution until it runs

out.

5. Meanwhile, mix the dye

solutions.

Measure out dye into a jar or cup

that can accommodate at least a cup of liquid.

For medium colors, measure 2 teaspoons of

dye powder. Some dyes need a higher concentration

- read the manufacturer's suggestions. For

lighter colors, use less dye. For dark colors,

use more dye.

For safety, I immediately close the powder

containers as soon as I'm finished measuring

the powder. I then wipe off the outside of

the powder container and dye cup with a wet

rag, to catch any powder that might be clinging

to the sides.

After measuring out the powder, add a very

small amount of warm water (1/2 teaspoon or

so). Use a stirrer to mix the powder and water

until it makes a paste. Add a little more water

and thin out the paste. Finally, add a cup

of warm water, in stages, stirring to dissolve

the powder. If you're using sealable jars,

you can put the lid on and shake it to mix

the solution.

6. Transfer dyes to applicator bottles, if

you choose. Bottles allow finer control over

dye placement, but you can also just pour directly

from the dye jars.

7. Remove yarn from the fixer solution and

squeeze out the extra liquid. Lay out the yarn

on your workspace.

8. Pour, spray, or squeeze dye onto the yarn.

Remember the color

wheel! If you place 2 colors next to each

other which are complimentary (opposites

side of the color wheel: e.g. red & green,

purple & yellow, blue & orange) they

will make BROWN. In general, unless you're

dyeing a rainbow, it's easiest to stick to

only 2 or 3 colors.

A note here: plant

fibers require MUCH more dye than protein

fibers. With acid dyeing, most of the dye

reacts and you're left with a clear or

slightly colored solution. Not so with

fiber reactive dyes - a lot of dye will

be left over even when the yarn is finished.

You need to apply more dye than you expect,

or you will get spots of undyed or under-dyed

yarn.

Once you've finished applying a dye, squeeze

the dyed yarn a bit so that the dye is transferred

through the entire cross section of the skein.

Otherwise, the yarn in the middle will be lighter

in color than the outer yarn. Less squeezing

= more color variegation.

9. Transfer the skein to a plastic bag, arranging

the skein so that differently-colored parts

of the yarn do not touch each other. Tie the

bag closed and leave in a warm place (at least

65 F/18 C). You need the yarn to stay wet and

warm for at least 12 hours, and preferably

24.

10. After 12-24 hours

(12 hours for pastels and silk, 24 for deeper

colors), open the bag and rinse out the

yarn with COLD WATER. Cold water removes

extra dye without causing it to react. You

must wash out all of the soda ash and most

of the extra dye. This part can be tedious,

there will be a lot of extra dye to rinse

out.

Dye can be rinsed out into a sewer system

without worry - it's not toxic. The soda ash

solution is weaker than most chemicals used

to unblock drains. The dyes WILL stain the

sink for a while, so use an outside hose or

a utility sink if you can.

11. After rinsing until

the water runs clear, I recommend you give

the skeins a final wash in Synthrapol, a

detergent and dye magnet. If there are any

unreacted dye molecules still on your skein,

it latches on to them, and keeps them from

staining other things they will touch. Synthrapol

requires hot water, and it will not work

if there is soda ash still in the yarn (hence

all the rinsing in the previous step). Follow

the manufacturer's directions for the Synthrapol

wash. After rinsing out the Synthapol, squeeze

out any extra liquid and hang the skein to

dry in a place away from the sun.

The dye solutions can be used for the next

couple weeks; they will gradually fade in intensity.

After two weeks I dump dye solutions down the

sink and mix up new ones. The soda ash fixer

can be kept indefinitely.

One more thing you should know about fiber

reactive dyeing: soda ash is caustic and it

will degrade fibers over time. You don't want

to leave your yarn exposed to it for a long

time. It's particularly hard on silk, which

is why I prefer to use acid dyes on silk. Because

of this, sometimes the dye process will change

the hand of the fiber, so that it feels rougher

after dyeing. If this bothers you, most dye

suppliers sell commercial-strength fabric softeners

which will re-soften the fibers.

Dye suppliers

Dharma

Trading Co

All dyes used in this article were Dharma's

Procion MX Fiber Reactive dyes.

Dye, supplies, and even un-dyed yarn.

Pro

Chemical & dye:

Also carries Fiber Reactive Procion MX dyes

and all dye supplies

References

Dharma

Trading Co

Their website contains many useful tutorials

and suggestions.

Paula

Burch's All About Hand Dyeing:

Paula has been dyeing fabric for many years

and this site is full of great information.

There is an emphasis on fabric, but most

of this can also be applied to yarn. |